How Aerospace Companies Use InfluxDB

By

Charles Mahler

Developer

Dec 12, 2025

Navigate to:

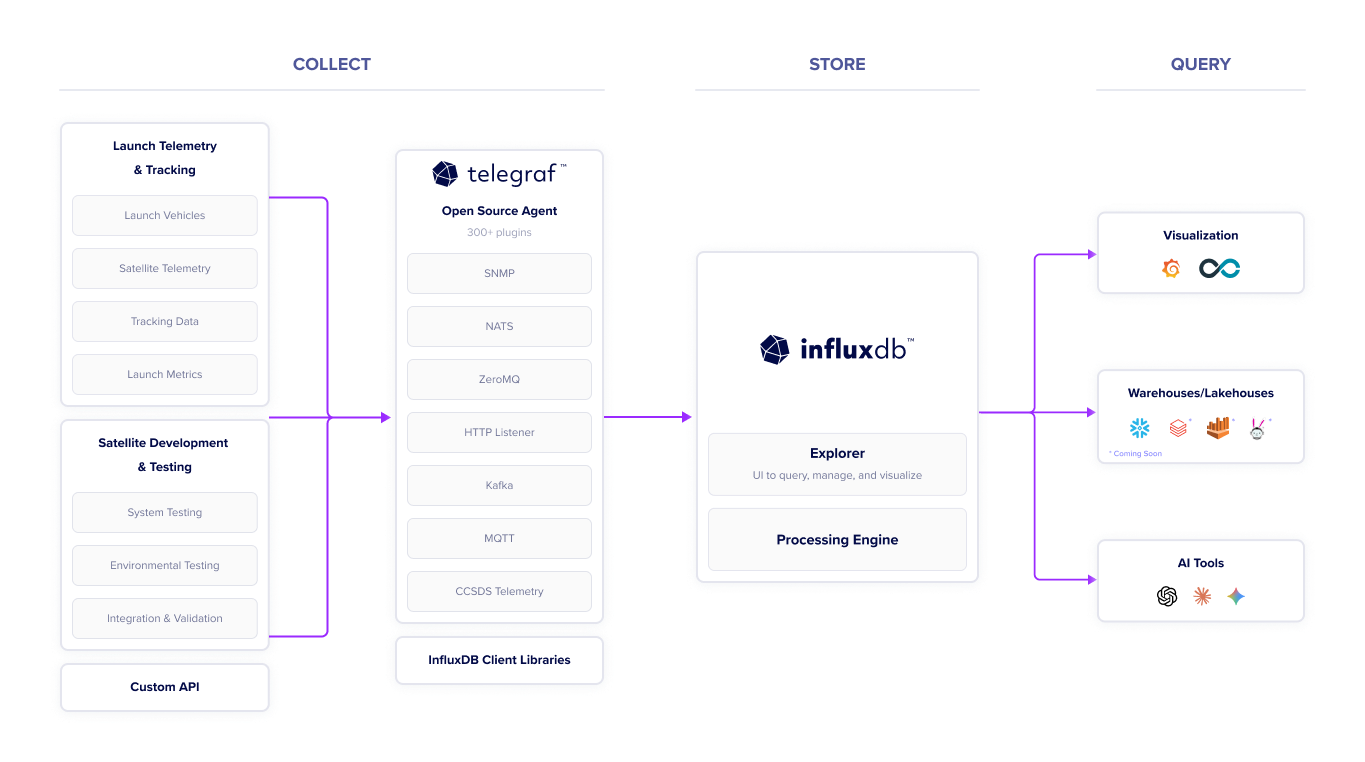

Over the past two decades, we’ve witnessed the instrumentation of virtually everything in the aerospace industry, from manufacturing floors to satellites orbiting Earth. And it’s no longer just NASA and other government organizations leading the charge. The commercial space industry has grown exponentially, with private companies developing everything from GPS satellites to electric VTOL aircraft.

This proliferation of sensors has transformed time series data from an afterthought into a first-class citizen. Companies store more and more data with higher granularity to become more efficient and reliable. Every component, every operation, and every mission generates massive volumes of time-stamped data that must be captured, analyzed, and acted upon in real-time.

Time series data across the aerospace industry

Time series data is critical in the aerospace industry to ensure safety and efficiency from the factory floor to flight operations. One InfluxDB customer has over 100,000 sensors on their factory floor—a single flight test can create billions of data points, and a 60-90 minute commercial flight generates 400-500 terabytes of data. Many aerospace companies are finding that the traditional data historians or relational databases they have used in the past aren’t viable for these workloads.

InfluxDB is an increasingly popular option for aerospace companies due to its performance, ease of deploying hybrid architectures, and developer experience. Here are a few examples of the benefits seen by developers who migrated to InfluxDB:

- The ability to perform real-time monitoring and anomaly detection, upgrading from queries that took up to 30 minutes with their prior database to only seconds with InfluxDB.

- Queries that analyze flight test data dropped from 15 minutes to seconds using InfluxDB.

- The ability to store data for years instead of weeks at the same cost or less.

- Schema-on-write made life easier for developers when working with (potentially) thousands of sensors sending different data.

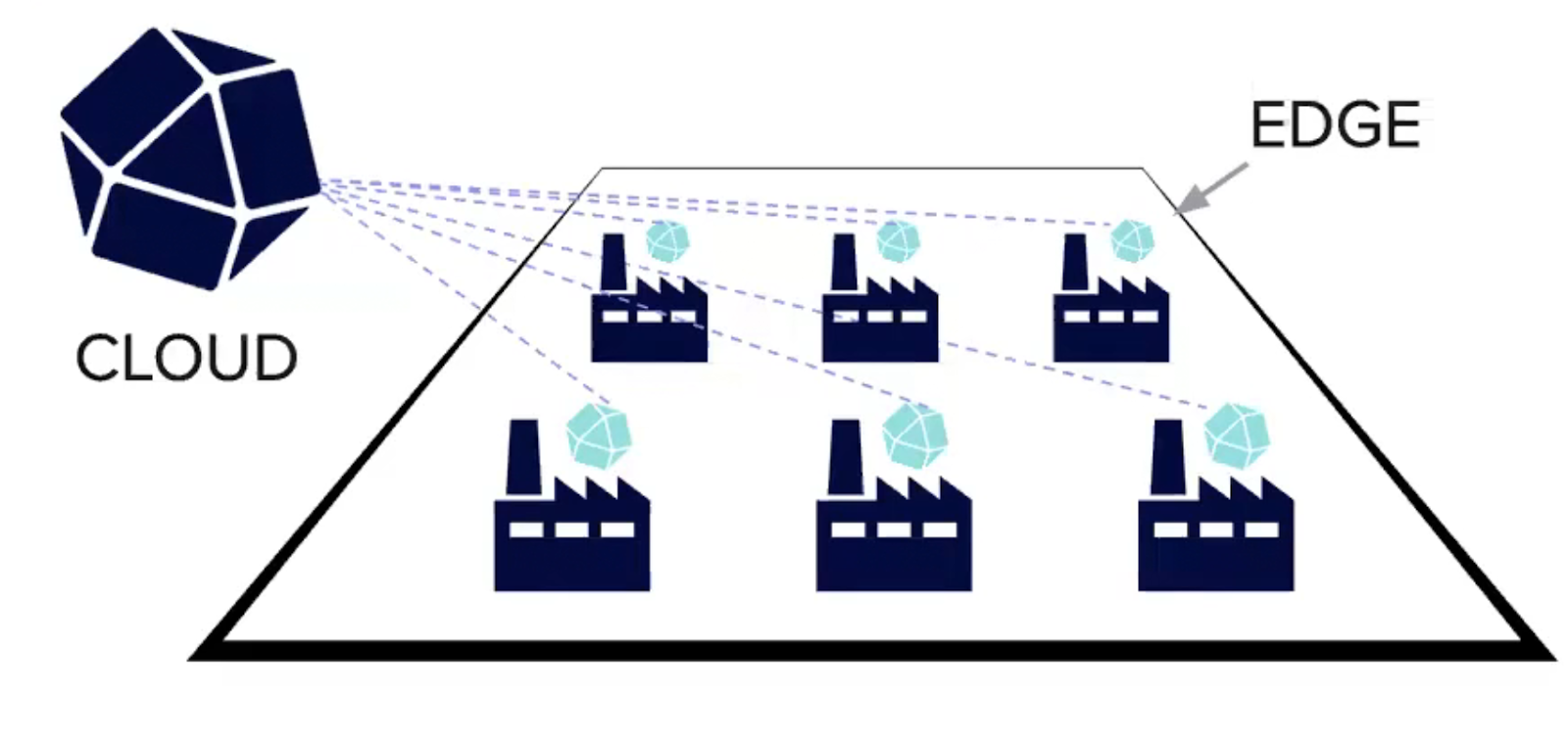

- Built-in functionality for moving data from locally installed InfluxDB instances to the cloud when edge devices have intermittent connectivity.

How aerospace companies use InfluxDB

Thales Space

Thales Space designs and operates satellites that provide a range of services, including telecommunications, navigation, and scientific research. The team uses InfluxDB to process and store their data, and to replay events for analysis. Leveraging InfluxDB enables them to collect and store data with higher granularity, improving the accuracy of the machine learning models used for fault detection and forecasting.

Eutelsat

Eutelsat operates over 600 low-orbit and geostationary orbit satellites. Each of these satellites produces over 50,000 unique telemetry values, and collectively, over 1 million data points per second. Eutelsat initially used Elasticsearch for its telemetry data but faced challenges with write performance, storage costs, and developer experience in transforming telemetry data into a format supported by Elasticsearch.

Eutelsat migrated to using Telegraf for data collecting and InfluxDB for storage. This gives the company unified telemetry data for analyzing spacecraft and ground-side data in a single place. The team uses this data for root-cause analysis by replaying events and proactive alerting. InfluxDB’s performance has also enabled Eutelstat to begin experimenting with machine learning models to improve predictive analytics and has provided more long-term data storage.

Aircraft Manufacturing

A major aircraft manufacturer used InfluxDB to modernize their factory monitoring system. Their existing architecture was built around AVEVA Wonderware and couldn’t keep up with increasing data volume. This setup had the potential to cause million-dollar delays and billions of dollars in losses if manufacturing errors led to airplane defects and regulatory issues.

To achieve their goals, they needed a database that allowed them to monitor each stage of the manufacturing process in real-time. After migrating to InfluxDB, they can track 3,000 different parameters per second from a variety of machines and sensors. InfluxDB also enabled a factory-wide view of their operations and eliminated data silos, creating a single place to track the entire manufacturing process. Another critical factor in choosing InfluxDB beyond performance was its security standards, which met the requirements for both commercial and military customers.

Satellite Communications

A satellite communications provider operating hundreds of satellites needed a new database as they scaled up to over 100,000 metrics per second. Their original solution was a cluster of Postgres instances that was expensive to maintain, operationally intensive to keep running, and had limited query performance, making many types of analysis impossible.

By adopting InfluxDB, engineers and data analysts were able to achieve better performance for both short-term queries required to ensure reliable service and long term queries that scan weeks to months worth of data. Another huge benefit of InfluxDB is the ability to use object storage for long-term data, as industry regulations require the customer to store data for over 10 years.

Looking forward

As the aerospace industry continues to evolve with increasingly sophisticated missions and launch operations, the need for specialized time series databases will only grow. InfluxDB represents a significant step forward compared to legacy solutions, offering the performance, scalability, and developer-friendly features that modern aerospace teams require.

If you are interested in more info about how InfluxDB is used for aerospace, check out this webinar.