InfluxDB for Real-Time Industrial IoT Analytics

The industrial IoT solution using InfluxDB provides real-time insight and analytics into manufacturing processes—collecting, storing, and visualizing data from sensors, devices, and industrial equipment.

#1

Time Series Database

Source: DB Engines

1B+

Downloads of InfluxDB

Take the complexity out of time series data management

Try InfluxDBTurn high-volume, high-velocity, high-resolution time series data into actionable intelligence without sacrificing performance.

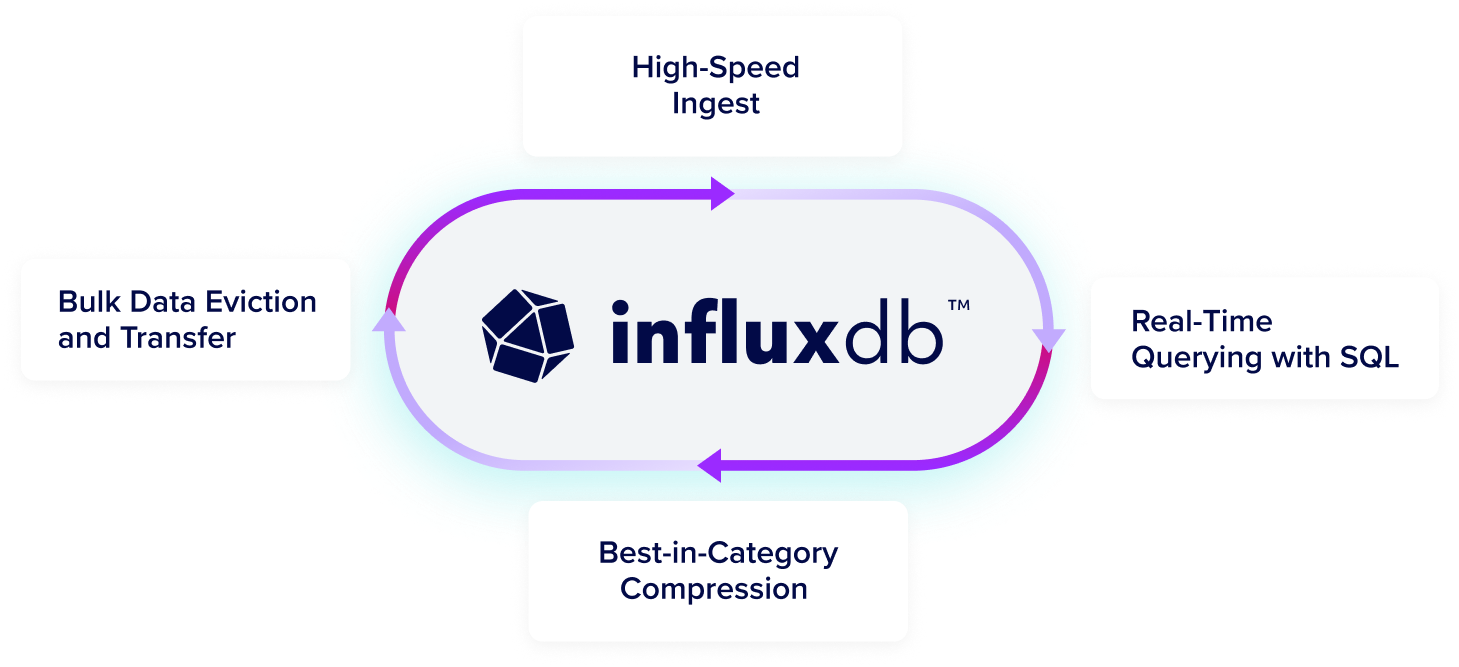

Get high-speed ingestion, real-time querying, and seamless scalability in a highly performant time series database that can handle unlimited volumes of time series data, even as data complexity and cardinality increases.

Run InfluxDB at scale in any environment in the cloud, on-premises, or at the edge. InfluxDB consists of the core database and storage engine, an API, and an ecosystem of tools and integrations to manage time-stamped data. Easily integrate with 5K+ prebuilt connections using Telegraf, our open source agent with 5B+ downloads.

Run InfluxDB 3 where you need it

Start for free, scale in seconds

Start NowFor small workloads and getting started

Deploy anywhere: on-prem, private cloud, edge, or multi-tenant cloud.

Secure, dedicated cloud infrastructure

Run a Proof of ConceptFor scaled workloads

Fully-managed, single-tenant service with unlimited scale, high availability, secure private connections, and enhanced Support.

Own your data with enterprise features

Run a Proof of ConceptFor scaled workloads

Control your infrastructure with unlimited scale, high availability, enterprise-grade security, and enhanced Support. On-prem, private cloud, and edge deployment.

Why InfluxDB

Limitless data collection

Ingest and analyze millions of time series data points per second without limits or caps.

Predict and prevent

Maximize uptime and prevent costly failures with real-time monitoring and preventative insights.

Real-time query

Data is immediately available for querying in InfluxDB, enabling real-time SQL queries and lightning-fast responses.

Why a purpose-built time series database?

Sensor data is time-stamped to help you understand how your processes and equipment are performing over time, facilitating further innovation and improvement.

Why InfluxDB for industrial IoT?

The industrial world has a history of modernizing processes in order to keep production running efficiently and safely while minimizing downtime. Yet many are locked in established data historian solutions that are costly and lack the methods needed to provide innovation and interoperability.

In contrast, InfluxDB—the open source time series database—inherently provides diverse design perspectives not available from a single software vendor. It provides the freedom to integrate with other solutions and allows you to adapt the code to fit your ever-changing system requirements.

Scalability

Collecting event data from your equipment is just the beginning. InfluxDB is a high-performance data store written specifically for time series data. It allows for high throughput ingest, compression, and real-time querying.

Open

Using open source tools provides the operator with the freedom to quickly innovate and never be locked in to a single solution that could easily and quickly become obsolete.

Built for developers

InfluxDB provides write and query capabilities with a command-line interface, a built-in HTTP API, a set of client libraries (e.g., Go, Python, and JavaScript), and Telegraf plugins for common data formats such as OPC-UA, ModBus, MQTT, and more. Manufacturing engineers use the purpose-built time series platform to process data at the edge and replicate it in the cloud.

Improve factory operations

- Use sensor data to gain insights into specific machine conditions (i.e., vibration, temperature, etc.)

- Aggregate all machinery data to create a single source of truth

- Better safety across manufacturing plants

Increase profitability

- Increase factory output by reducing silos across organizations

- Enable predictive maintenance, resulting in reduced machine downtime

- Simplify processes by increasing overall equipment effectiveness

Modernize the manufacturing industry

- Replace legacy historians, allowing for better Industry 4.0 monitoring

- Create digital twins used to detect reliability threats

- Able to ingest sensor metrics quickly at scale

Related resources for developers:

InfluxDB Integrations

Get Blueprint

InfluxDB Edge Data Replication

Free InfluxDB training

“We needed a database with historical capabilities—InfluxDB was a perfect choice as it is a high-performance database optimized for storing time series data.”

Dr. Göran AppelquistCTO, Crosser

Open data standards drive performance and interoperability

InfluxDB 3 is built in Rust and the FDAP stack—Flight, DataFusion, Arrow, and Parquet—leveraging Apache-backed technologies to efficiently ingest, store, and analyze time series data at any scale.

Try InfluxDBF

Flight for efficient columnar data transfer

D

DataFusion for high-performance querying

A

Arrow for optimized in-memory columnar analytics

P

Parquet for high-compression storage

InfluxDB’s columnar database supports time series data at a lower TCO

See ways to get started

Loved by developers, trusted by enterprises

65M+

daly events processed

45x

more resource efficient

Siemens Energy

“[We] long used InfluxDB open source... Moving to commercial InfluxDB was a strategic move to unify our data infrastructure, ensuring we have the reliability, scalability, and real-time performance to keep pace with production... and proactive maintenance.”

Jan Petersen

Senior Manufacturing Engineer

500M+

Metrics collected daily

Mission-critical monitoring

Real-time data access for queries

LOFT ORBITAL

Space Made Simple: How Loft Orbital Delivers Unparalleled Speed-to-Space with InfluxDB Cloud

Read Case Study65M+

daly events processed

45x

more resource efficient

CAPITAL ONE

"InfluxDB is a high-speed read and write database. The data is written in real-time, you can read it in real-time, and while reading, you can apply your machine learning model. So, in real-time, you can forecast and detect anomalies."

Rajeev Tomer

Sr. Manager of Data Engineering

50%

lower total cost of ownership

100K

real-time metrics with simplified deployment

TERÉGA

Teréga Replaced Its Legacy Data Historian with InfluxDB

Lorem ipsum

Lorem ipsum dolor sit amet consectetur.

65M+

daly events processed

45x

more resource efficient

WIDEOPENWEST

"I was blown away with how easy it was to install and configure InfluxDB. The clustering was easy. The documentation was great, and the support has been second to none."

Dylan Shorter

Engineer III, Software and Product Integration Engineering

45%

Less equipment downtime

10%

Reduced waste

MAJIK SYSTEMS

From Reactive to Proactive: How MAJiK Systems Embraced Predictive Maintenance with InfluxDB and Time Series Data

Dylan Shorter

Engineer III, Software and Product Integration Engineering

65M+

daly events processed

45x

more resource efficient

JU:NIZ ENERGY

“With InfluxDB Cloud Dedicated, the great thing is that we don't need to think about data storage costs or usage anymore because data storage gets way cheaper.”

Ricardo Kissinger

Head of IT Infrastructure and IT Security